The past few years have seen the field of robotics focus increasingly on developing technologies which allow robots to handle more accurate and delicate tasks.

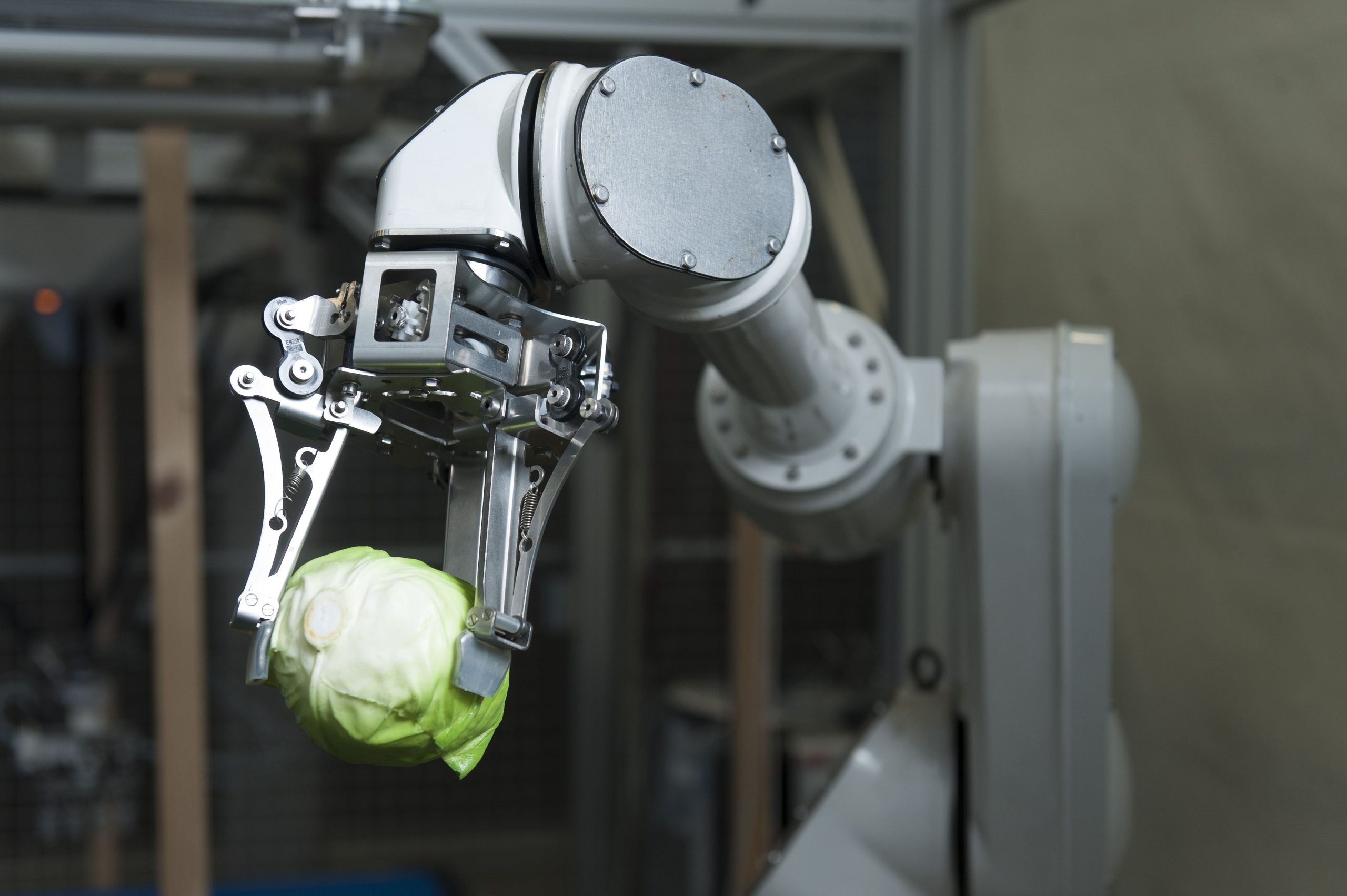

A TU start-up called Lacquey has developed a robot-arm that is capable of handling more delicate tasks in the food industry’s production lines, potentially changing the way the Netherlands produces food.

Located in YesDelft incubator, where it has been since 2010, Lacquey received a sizeable investment from FTNON (Food Technology Noord-Oost Nederland) who bought a majority share in the company at the start of March. CEO Richard van der Linde said that although they originally aspired to be an independent company, “In reality, it doesn’t work like that. You need to team up with one of these few players who rule the world of food equipment.”

The technology they are developing first originated within the walls of TU Delft. Phd candidate Gert Kragten developed the technology as part of his research which was funded by a baggage handling company wishing to automate their process. What he developed was a robot which had the potential to pick up and move objects of varying sizes, weights and malleability, something most robots are currently unable to do. His method uses under-actuation, where the robot gripper uses a single motor to control the force of the fingers. This is far more important than controlling their movement, and makes the robots “easier, cheaper, and more reliable” according to Dr. Just Herder, Kragten’s colleague and an expert in the field. This under-actuated gripping technology was patented by TU Delft in 2009 and then bought by Lacquey, with the intention of applying technology to the fresh food industry.

What Lacquey aims to do, according to van der Linde, is “replace dull, heavy and tedious human jobs with more intelligent and hygienic automated solutions.” As the CEO of the company, Van der Linde is just as much a businessman as a self-professed robotics ‘geek’, managing to spin Lacquey’s technology as more than just a way to reduce production costs and increase efficiency and hygiene. He considers it a way to reduce damaging repetitive labour currently done by humans, and even a potential solution to food security. “From the raw material to the fork, 40% of food is spilled. I hope that automation will not only replace dull tedious labour, but will help in optimising yields to decrease waste,” he said.

The fresh food industry is one of the largest in the Netherlands, and so while the automation of the repetitive labour it currently employs would make a dent in food wastage, it would not be until the long term. Additionally, being one of the largest industries, replacing low-skill labour with robots may be met with resistance, as the Netherlands is job-market is already a climate where, according to research from Groningen University, low skilled workers are being squeezed out. Dr. Herder asserts that in his opinion this type of robot.

Comments are closed.