With their latest genetically modified yeast, TU Delft researchers think they can boost bioethanol production from agricultural waste. “Within two years the first full-scale plants for second generation bioethanol will have started production.”

Bioethanol is currently the largest product of industrial biotechnology, accounting for an annual world production of 65 billion litres, which is mainly intended as fuel for cars. Just like beer and wine, bioethanol is made by the yeast Saccharomyces cerevisiae from sugars obtained from plant biomass. “With such huge quantities, each amelioration of the fermentation process leading to some percentages more yield has a big impact on the industry”, says professor Jack Pronk. He and his colleagues from the Kluyver Centre for Genomics of Industrial Fermentation genetically modified yeast, enabling it to produce about ten percent more ethanol. Their discovery was published last week in the scientific journal Applied and Environmental Microbiology.

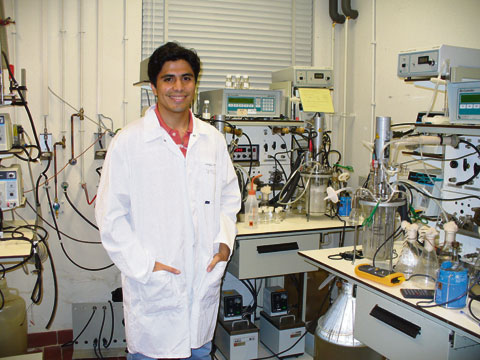

The lead author of the article, Victor Guadalupe Medina (MSc), added a single gene from a bacterium to the yeast, which, in addition to sugar, enabled it to also convert acetate to ethanol. At the same time, Medina knocked out two yeast genes required for the transformation of sugars into glycerol instead of ethanol. Both acetate and glycerol are undesirable byproducts of the bioethanol production process.

“For bulk processes, this increase in yield can make the difference between a ‘go’ or ‘no go’ for industry”, Pronk says. The microbiologist refers specifically to the second generation bioethanol industry. Bioethanol should preferably be produced from resources that do not compete with food production. For this reason, efforts are made to produce second generation bioethanol using agricultural residues, such as wheat straw and corn stover, instead of for example sugar cane, beets or maize.

During the processing of these agricultural residues – in which sugars are released from plant polymers – significant quantities of acetate are formed. Acetate can slow down or even halt bioethanol production by yeast.

It is the second important discovery from TU Delft’s biotechnology department that brings second generation bioethanol a step closer. In recent years, Pronk and colleagues made headlines when they engineered a yeast that was able to convert the sugars xylose and arabinose into ethanol. Yeast previously had a hard time digesting these molecules, which occur in large amounts in agricultural residues. One of the genes he added to the yeast came from a fungus derived from elephant feces, a detail that contributed to the extensive press coverage.

“My colleague, dr. Ton van Maris, and I were teaching students about a biochemical pathway in the bacterium E.coli, when suddenly it appeared to us”, Pronk recalls. “The formation of glycerol as a byproduct in sugar fermentation was not inevitable, as had always been thought. We only had to insert the gene encoding for an enzyme (acetaldehyde dehydrogenase) from the bacterium into the yeast genome. As an extra consequence more ethanol would be formed and toxic acetate would be consumed. Victor Guadalupe very creatively turned this wild idea into a proof-of-principle.”

Now follow-up research on the transfer of this concept to industrial yeast strains and real-life process conditions is required. Among the tests to be conducted will be those that determine whether the genetically modified yeast can survive under these conditions. “But I’m confident we will get this concept to work”, Pronk states.

The TU Delft yeast researchers, who have applied for a patent on their invention, hope to intensively collaborate with industrial partners, in order to accelerate its industrial implementation. Pronk believes the industry advances quickly now: “Within two years the first full-scale plants for second generation bio ethanol will have started production.”

Het is de faculteit Bouwkunde niet gelukt bij de begroting op een bedrag van -3,2 miljoen euro uit te komen. Een aantal afdelingen kan niet verder bezuinigen, waardoor een extra tekort van 515.000 euro zou ontstaan. Het college heeft daarom besloten dat het onderwijs beroep kan doen op een extra anderhalve ton. Voor promotieonderzoek aan de Delft School of Design is een ton extra beschikbaar.

Comments are closed.